Written by Shwaira Solutions

21 September 2025 | 4 min read

Introduction: What Are Digital Twins?

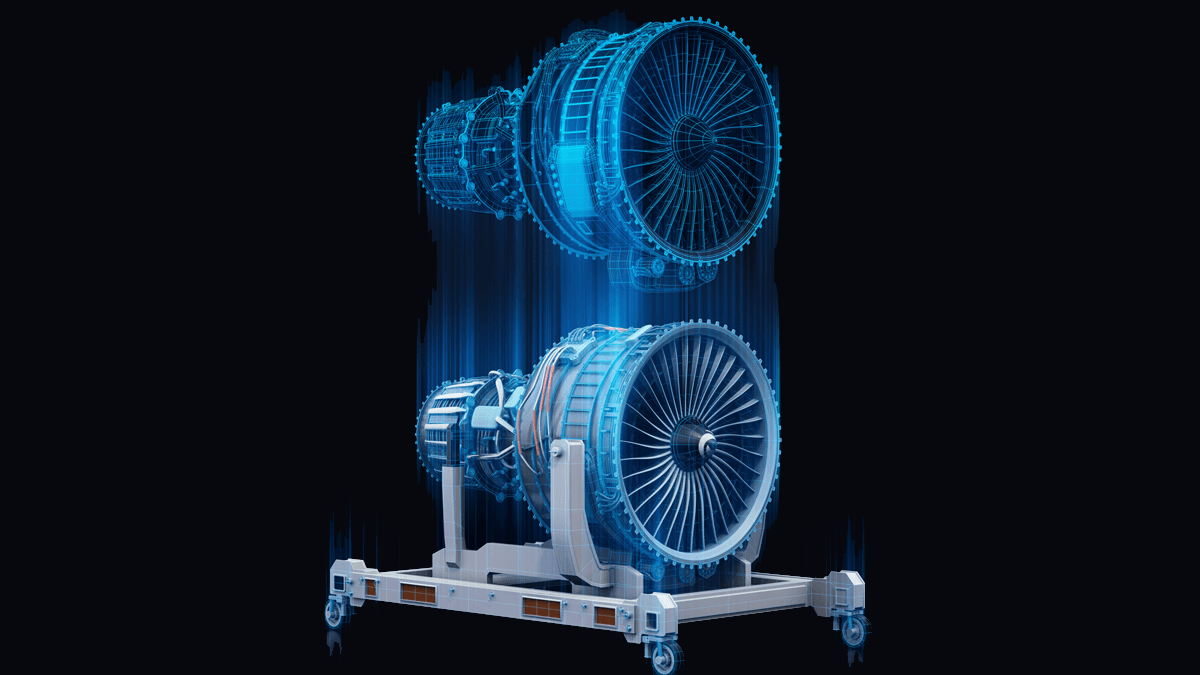

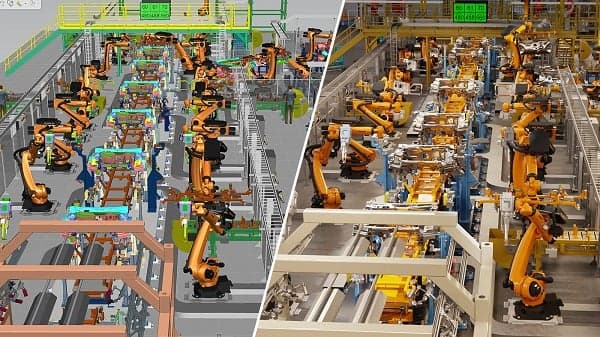

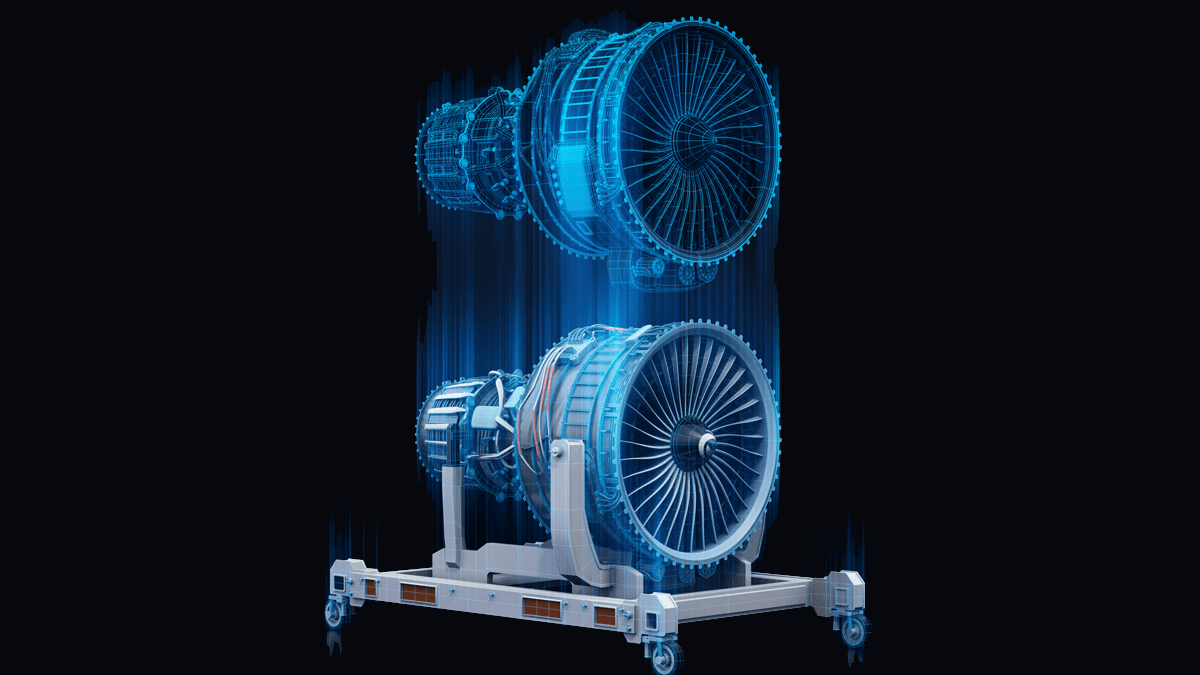

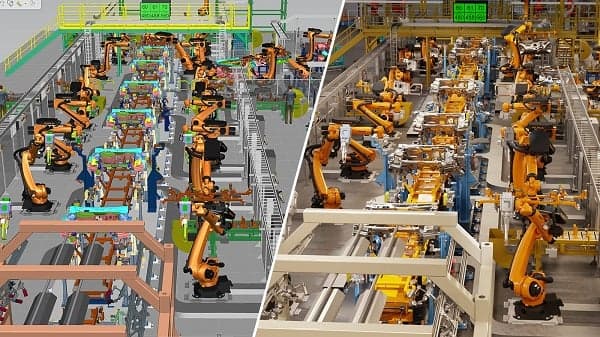

In the era of Industry 4.0, manufacturers are moving beyond physical systems alone. A digital twin is a virtual replica of a physical asset, process, or system that continuously syncs with real-world data. It allows companies to simulate scenarios, detect inefficiencies, and predict outcomes - without disrupting live operations.

Why Digital Twins Matter in Manufacturing

Traditional monitoring and testing can’t keep up with today’s demands for efficiency, customization, and uptime. Digital twins enable manufacturers to:

- Test process changes in a virtual environment before applying them.

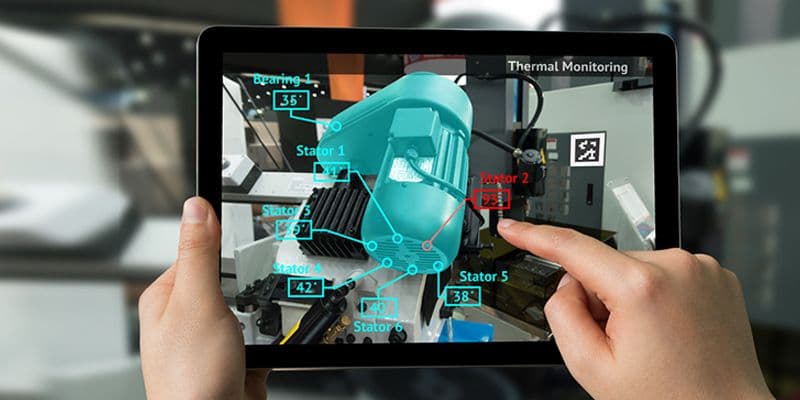

- Detect equipment issues in advance with real-time data.

- Reduce downtime by shifting from scheduled to predictive maintenance.

- Optimize production lines to balance speed, quality, and cost.

The result? Smarter decisions, faster innovation, and safer operations.

How Digital Twins Work

A digital twin integrates multiple technologies into a unified system:

- IoT Sensors → Capture real-time machine and environmental data.

- Cloud Platforms → Store and process massive data streams.

- AI & Analytics → Identify patterns, predict failures, and optimize workflows.

- XR Visualization → Enable immersive interaction with the twin for training and collaboration.

This combination provides a living, evolving model that mirrors its physical counterpart.

Shwaira Solutions’ Approach

At Shwaira Solutions, digital twin solutions are designed with scalability and adaptability in mind. Through our Experience Engineering framework, we deliver:

- 📡 Industrial IoT Integration - Deploying connected sensor networks for real-time visibility.

- ⚙️ AI-Driven Predictive Insights - Leveraging machine learning to forecast outcomes and improve efficiency.

- 🌀 Simulation with XR & Omniverse - Creating immersive digital replicas for operator training and process validation.

- 📊 Centralized Dashboards - Enabling intuitive monitoring and decision-making with actionable insights.

- 🏭 Smart Manufacturing Optimization - Applying twin data to streamline production, reduce costs, and extend asset life.

This holistic approach helps manufacturers transition from reactive operations to proactive innovation.

Conclusion

Digital twins are no longer a futuristic concept - they are a practical necessity for manufacturers who want to remain competitive. By combining IoT, AI, and immersive XR technologies, businesses can optimize operations, reduce downtime, and accelerate product innovation.

At Shwaira Solutions, we help organizations build and scale digital twin systems that deliver measurable results today, while preparing them for the factories of tomorrow.

Let's Talk About Your Next Big Idea

Collaborate with experts to architect intelligent systems that bring your vision to life.