Written by Shwaira Solutions

20 September 2025 | 6 min read

Introduction: The Shift from Reactive to Predictive

In today’s competitive business environment, organizations can’t afford unexpected equipment breakdowns or prolonged downtime. Traditional methods like reactive maintenance or preventive maintenance often lead to inefficiencies and wasted resources. Predictive maintenance (PdM), powered by Artificial Intelligence (AI) and the Internet of Things (IoT), enables businesses to forecast equipment issues before they happen, reducing downtime and improving efficiency.

Why Predictive Maintenance Matters

Unplanned downtime can be one of the most expensive challenges for asset-heavy industries. Predictive maintenance reduces downtime, extends asset lifespan, and optimizes maintenance schedules, ensuring smooth operations. For industries like manufacturing, automotive, healthcare, and energy, predictive maintenance is becoming a strategic necessity.

How Predictive Maintenance Works

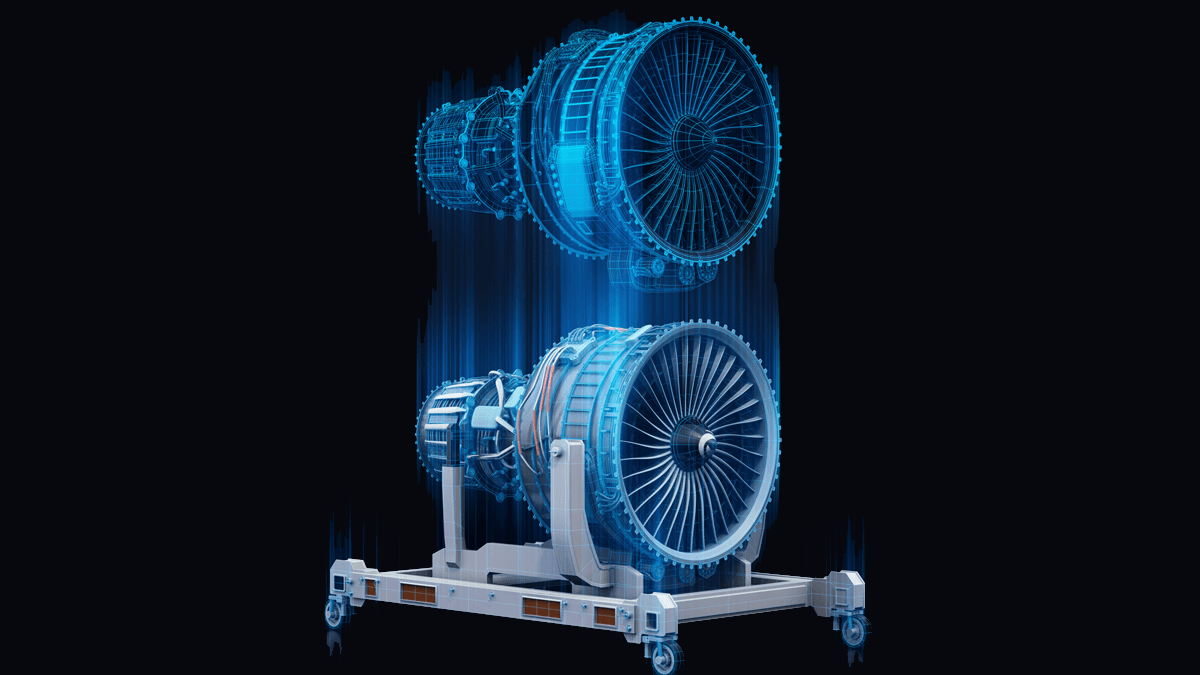

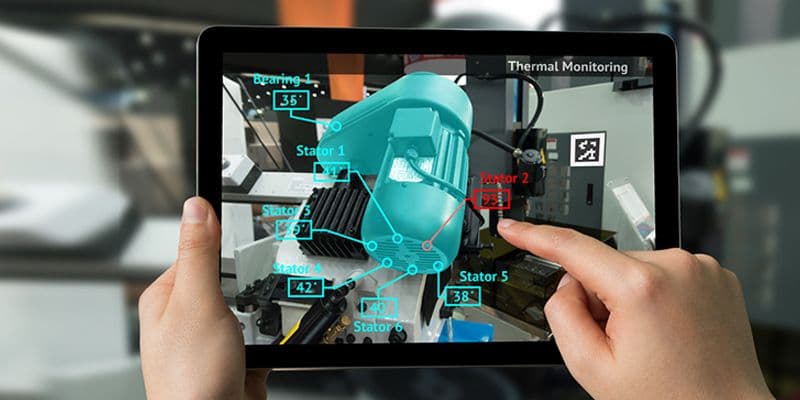

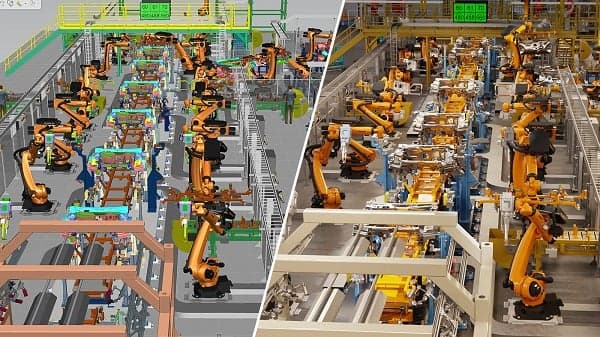

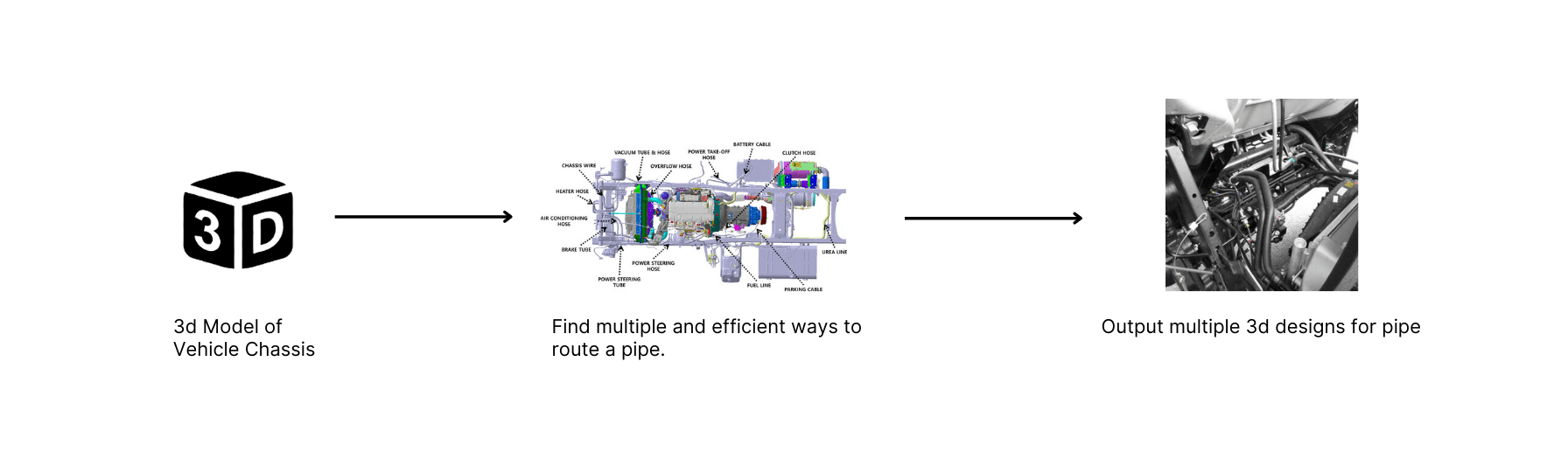

Predictive maintenance combines IoT, real-time analytics, and AI to deliver actionable insights. IoT sensors capture continuous data such as vibration, temperature, or energy usage. Digital twins simulate equipment virtually. Machine learning models analyze patterns and predict failures, while dashboards provide operators with proactive alerts to take timely action.

Shwaira Solution's Approach

At Shwaira Solutions, predictive maintenance goes beyond installing sensors or dashboards. Our approach follows the Experience Engineering framework, ensuring solutions are impactful, scalable, and future-ready:

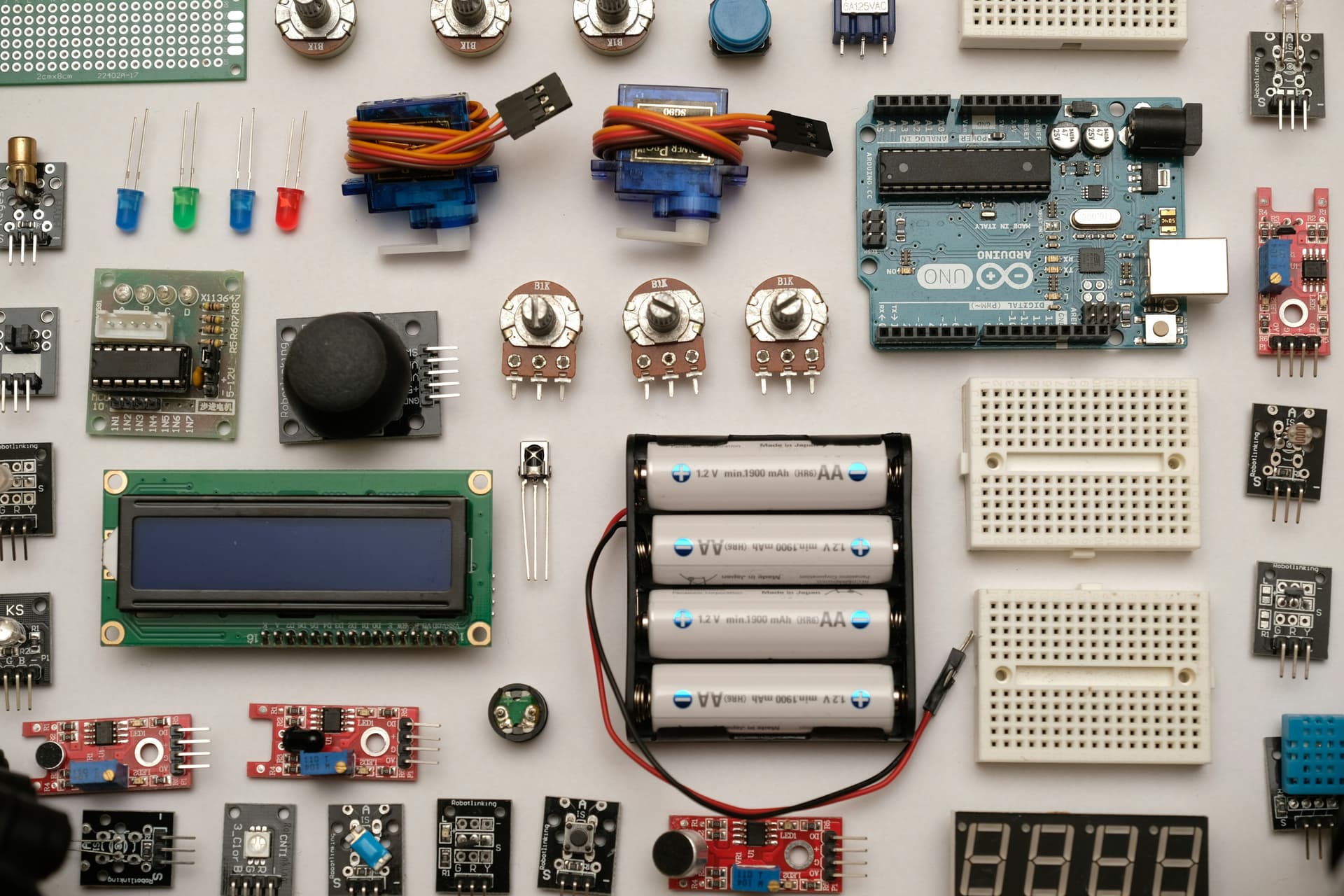

- 📡 Industrial IoT - Deploying connected sensor networks for real-time monitoring of assets.

- 🤖 AI & Analytics - Designing machine learning models to detect anomalies and optimize schedules.

- 🌀 Digital Twin Integration - Building live simulations of physical assets to test scenarios before they occur.

- 📊 IoT Controllers & Dashboards - Centralized platforms for device management, automated alerts, and visibility.

- ⚡ Smart Maintenance Systems - Enabling proactive, data-driven maintenance that evolves with usage patterns.

Let's Talk About Your Next Big Idea

Collaborate with experts to architect intelligent systems that bring your vision to life.